Printed circuit boards with stable quality ensures designed function achievable.

Our team has a blend of technical knowledge, attention to detail, and creativity to solve complex engineering challenges.

General workflow

√ Requirement Analysis: Define board size, layers, and key components.

√ Schematic Design: Create circuits and assign footprints.

√ Layout: Place components and route traces.

√ Simulation: Validate signal/power integrity.

√ Design Review: Collaborate with engineers and manufacturers.

√ Manufacturing Output: Generate Gerber files and submit to the fab house.

√ Delivery: Present the sample for prototype-build and prepare for mass

production once we get the 'OK' to go.

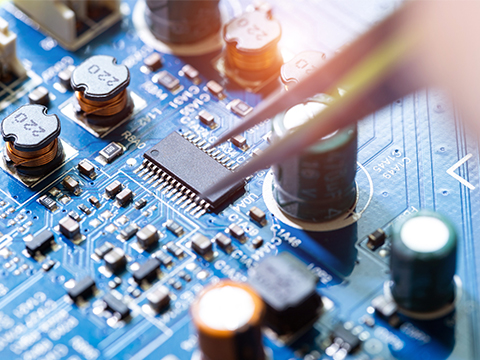

SMT THT Mixed-Technology and DIP assembly lines used for reliable builds

Standard processes

√ Design & File Preparation:Provide PCB layout data, Bill of Materials, Pick-and-Place File

√ Solder Paste Application

√ Inspection: Automated Optical Inspection (AOI) checks paste volume/alignment.

√ Component Placement

√ Reflow Soldering: Conveyor Oven, Preheat, Reflow& Cooling

√ Through-Hole (THT) Component Assembly

√ Wave/ Manual Soldering

√ Inspection & Quality Control: AOI X-Ray ICT

√ Final Assembly & Testing: Programming, Functional Testing, Packaging

Cost-effective, genuine components supply network ensuring timely delivery

Throughout Services

√ BOM Analysis, validate part numbers, specifications, and alternates (if available).

√ Sourcing Components Suppliers: Identify authorized distributors,manufacturers,

and value-added resellers only

√ Cost Negotiation

√ Quality Assurance

√ Inventory Management: Balance just-in-time delivery to minimize storage costs.

√ Logistics & Delivery: Coordinate shipping, customs clearance, and delivery

timelines. Track orders to avoid production delays.

√ Risk Mitigation: Address supply chain disruptions, identify alternates or redesign

options for obsolete or long-lead-time parts.

Automotive

Medical

Communication

Industrial

Home&Life Security

IoT

Consumer

Smart Wear